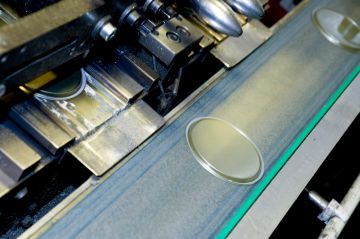

Suitable for common lining systems

Suitable for all common feeding systems

Optimized for demanding closing conditions

Vacuum-, steam and hot filling

Pasteurisation and sterilization

Good pressure, temperature and steam resistance

Good to very good adhesion on all common lacquers

Shelf life: 10 months

Food contact approved

Suit Food

Biotest

Food products - Advanced technology

All WAKOL Sealing Compounds with advanced technology++ are proactively designed even to meet tomorrows regulatory challenges.

These are products

without usage of mineral oil based plasticizers or film formation aids (no MOSH/MOAH)

with very low extraction profile and low occurrence of NIAS

styrene free formulated

All WAKOL Sealing Compounds with advanced technology+ are proactively designed for upcoming regulatory challenges.

These are products

without usage of mineral oil based plasticizers or film formation aids (no MOSH/MOAH)

with very low extraction profile and low occurrence of NIAS

VAE (vinyl acetate ethylene) based products

Special Advantages

Very good fat & oil resistance

Suitable for hot oil filling

Styrene free

Special Advantages

Suitable for slow- to high-speed liners

Excellent water resistance

Good adhesion on all common lacquers

Suitable for electrocoating as post-repair process

Highly cost-efficient

NIAS: very low level

Properties range

Solid content: 59%

Viscosity (WPV 74): 480 mPas

Density dry: 1,40 g/cm³

Density wet: 1,26 g/cm³

Colour: grey

Additional Information

Certificate available

Regulation (EC) 1935/2004/EG

FDA 21 CFR 175.300

Mercosur

Brazilian Resolution RDC

CH-Bedarfsgegenständeverordnung

NIAS screening

Special Advantages

Suitable for slow- to high-speed liners

Good water resistance

Good adhesion on all common lacquers

Suitable for electrocoating as post-repair process

Highly cost-efficient

NIAS: very low level

Properties range

Solid content: 40-59%

Viscosity (WPV 74): 310-480 mPas

Density dry: 1,37-1,50 g/cm³

Density wet: 1,17-1,26 g/cm³

Colour: grey

Additional Information

Certificate available

Regulation (EC) 1935/2004/EG

FDA 21 CFR 175.300

Mercosur

Brazilian Resolution RDC

CH-Bedarfsgegenständeverordnung

NIAS screening

SBR (styrene butadiene rubber) based products

Special Advantages

High water resistance

Steam closing and hot filling possible

Special Advantages

Suitable for medium- to high-speed liners including multi-head liners

Very good adhesion on all common lacquers

Suitable for electrocoating as post-repair process

Cost-efficient

Properties range

Solid content: 60%

Viscosity (WPV 74): 400 mPas

Density dry: 1,35 g/cm³

Density wet: 1,17 g/cm³

Colour: grey

Additional Information

Certificate available

Regulation (EC) 1935/2004/EG

FDA 21 CFR 175.300

Mercosur

Brazilian Resolution RDC

Special Advantages

Suitable for slow- to high-speed liners

Good adhesion on all common lacquers

Good fat and oil resistance

Highly cost-efficient

Free from white oils/gum-rosin derivates

NIAS: low level

Properties range

Solid content: 52-60%

Viscosity (WPV 74): 350-500 mPas

Density dry: 1,55 g/cm³

Density wet: 1,23-1,28 g/cm³

Colour: grey

Additional Information

Certificate available

Regulation (EC) 1935/2004/EG

FDA 21 CFR 175.300

Mercosur

Brazilian Resolution RDC

NIAS screening

Special Advantages

Suitable for medium- to high-speed liners including multi-head liners

Very good adhesion on all common lacquers

Long-term market experience

Properties range

Solid content: 60%

Viscosity (WPV 74): 400-500 mPas

Density dry: 1,51 g/cm³

Density wet: 1,27 g/cm³

Colour: grey

Additional Information

Certificate available

Regulation (EC) 1935/2004/EG

FDA 21 CFR 175.300

Mercosur

Brazilian Resolution RDC

NIAS screening